FAQs

What is LRO ?

![]() stands for Liquid Refrigerant Optimization. It is a product created from years of research and development focused on minimising the quantity of refrigerant gas needed in a refrigeration system while increasing efficiency, maintaining reliability, and reducing running costs.

stands for Liquid Refrigerant Optimization. It is a product created from years of research and development focused on minimising the quantity of refrigerant gas needed in a refrigeration system while increasing efficiency, maintaining reliability, and reducing running costs.

Does it work?

Yes. Refer to testimonials page, on new and existing plant installations, refrigerant quantities have been successfully reduced by up to 80% and running costs reduced with no issues on reliability, efficiency or system capacity.

Do I need to replace my entire refrigeration system?

No. ![]() is a relatively simple retrofit to an existing system where possible.

is a relatively simple retrofit to an existing system where possible.

Can all plant be converted?

NO ongoing development is still underway. However, a free assessment of your plant is available by a visit from one of our engineers.

Click here to make an assessment appointment.

How much does it cost?

Every project or job is different with many variables. Call us for a site visit and assessment.

In many cases, an LRO system can be retrofitted for less than the replacement cost of the existing refrigerant gas charge.

Why should I consider installing LRO?

With refrigerant gas wholesale price increased up to 400% since July 1st, 2012, a typical gas leak in a commercial installation can run into tens of thousands of dollars.

LRO eliminates your exposure to expensive repair costs while reducing running costs and overall carbon foot print.

Further advantages of LRO system:

- Divides entire system into smaller compact units,

- Reduces refrigerant charge by up to 80%,

- Reduces running costs,

- Reduces customers exposure to expensive gas replacement costs,

- Reduces business carbon footprint,

- Reduces total refrigerant piping length and number of fittings,

- Significantly reduces potential gas leak points.

What is my exposure to Increased Refrigerant Prices?

These following factors will define the level of impact of refrigerant prices will have on your business:

- Type of Refrigerants (GWP value)

- Quantity used of Refrigerant (kg, per plant & per site)

- Acknowledged loss rates (10% to 30% of charge on average per year)

How much would it cost if I had a gas leak?

Refrigerant prices from wholesalers are unstable and have increased DRAMATICALLY.

For example:

- Up 400% for R404A

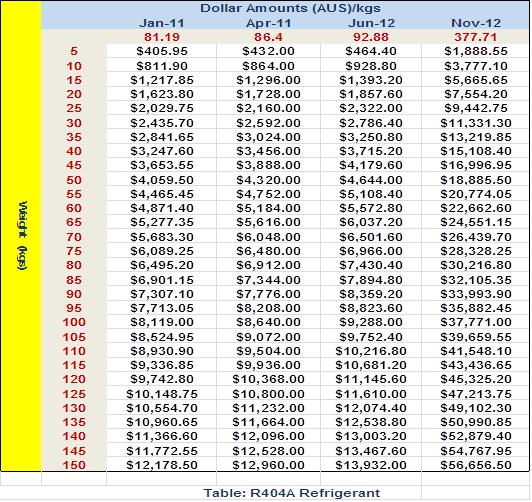

Although, each business faces different challenges in relation to their risks of refrigerant loss and results a down turn in production. The table below compares and summarizes what would have businesses absorbed before July 2012 and after July 2012.

What are factors impacting refrigerant loss on my system?

Most refrigeration systems assembled from a collection of components, parts, and materials that are installed on a client’s sites to suit each organizational or individual requirement. These refrigeration plants are every so often altered over time without design consideration and restricted only in quality control as to compliance or standards. Consequently the modification in type, suitability, quality and condition differs significantly.

As a result some of the main causes that are likely to impact on refrigerant loss are:

- System type or design, relates to: compressor equipment shaft seals, old, overloaded or damaged equipment.

- Concerns associated with installation, such as: age of the installation, quality of the original installation, & condition of the plant

- Issues with piping and other materials utilised, such as: length of pipe runs, physical damage to pipe and excessive use of mechanical joints in pipework and valving

- Components failures

- Issues related with electricity: electrical shorts.

- Refrigerant and oil condition (risk of burn out contamination)

- Poor power quality (risk of sealed motor burns out and refrigerant contamination)

- Poor or irregular maintenance procedures

- Expansion or contraction

In addition, there are new risks occurred due to the massive increase in refrigerant cost:

- Security issues: thefts, in transport, storage and usage

- Supply Continuousness & Availability, especially if refrigerant gas is needed in large quantity.

- Insurance costs

- Liability on warranty of new parts & components